OEM, EMS Business

TOP > OEM, EMS Business

Reason Why Azden is selected

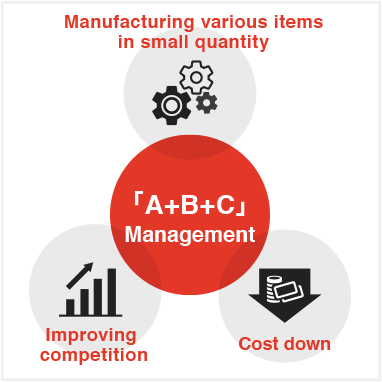

Total cost saving

The biggest value we offer in OEM/EMS business to a customer is reduction in total cost *1. The development a customer can put in OEM and reduction in design cost. And customer's product will be completed in a short due date, high quality and a low cost by it's consistent, and doing one part supply by us, electronic component mounting and assembly by production. The quantity a customer needs, it's timely and, I contribute to a cost reduction by the total including the stock (part and finished goods) and the customer service cost after market investment by being high-quality and delivering.

*1 Total = Development Cost + Manufacturing Cost + Material inventory + Assembling items + Transportation + after-service

Know-how of the various kind in small quantity

We keep maintaining 100% domestic production. It is reason we have accumulated the know-how of production of the various kind in small quantity. When aiming at low-cost production in foreign countries, the one which becomes problem is huge quantity production. We kept being particular about a domestic production and even a small lot was low in cost and we were studying the system that you can produce. A product, each production process is observed thoroughly, and it's shortest and produces only the necessary quantity using minimum resources (humanly, physical). It's possible to suppress a part, a beginning and the total stock of finished goods in a minimum, and it's possible to make the necessary funds in a customer a minimum.

Made In Japan

There is Iwate factory which is our main production base in Hanamaki-shi, Iwate. A delinquent can contribute to the quick correspondence when occurring, and reducing on a due date by producing at a domestic factory. It'll be also done easily that customer's quality control section inspects and visits a site. The cost corresponding to the badness and the customer service cost of the customer fall remarkably compared with overseas production by doing high-quality production made in Japan. A timely delivery to the domestic market also becomes possible.

Manufacturing Method

A product, the most suitable standard work is prescribed to each. Reduction in total cost, first, I think, analyze whole process flow to finished goods including part supply method thoroughly and suppress stock of a part and stock of a beginning and finished goods to the utmost. The necessary thing is continued while improving the manufacturing system with which only the necessary quantity is made every day.

Introduction of owing facility

AZDEN is possessing the rich equipment to achieve a high-quality domestic continuous production.

A surface mounting/automatic insertion/foundation assembly/assembly of finished goods/mechanical pressing/plastics molding/, it's blown, processing... arriving at the painting/serigraph/laser press/pottery/adjustment check/lead line terminal pressure

I'll respond to all needs. Details of equipment see the following, please.

Service Flow

For your inquire we propose the details of quotation for each products individually. Please also inquire preliminary factory tour and meeting any time. We have a confidence we can provide best cost in world market for the various kind item in small quantity. Please consult with us when you are not able to find the manufacturing service for small quantity production.

Contact

Kindly contact to below for OEM and EMS business.

- Mail:sales@azden.co.jp

- Phone:+81-422-55-5115